Introduction: Facility Profile and Project Stakes

A commercial facility in New Jersey relied on an aging boiler plant for space heating and hot water. The existing equipment still ran, but it was hard to keep the system reliable without wasting fuel, especially during shoulder seasons and partial‑load conditions.

Industrial Combustion Associates (ICA) was brought in to design and supply a boiler package that would modernize the plant without a full mechanical room rebuild. The owner wanted:

- Reliable capacity during peak winter conditions

- Lower fuel usage across the heating season

- Controls that building staff could understand and manage confidently

Any upgrade also had to respect existing space, venting, and service constraints in the boiler room.

Project Overview: Existing System Constraints and Risks

Before the upgrade, the boiler plant showed a familiar pattern of issues:

- Limited turndown and older burner controls led to frequent short‑cycling at light loads.

- Combustion tuning drifted over time, so efficiency was difficult to maintain.

- Operators had minimal real‑time feedback on firing rate, air‑fuel ratios, or alarm history.

In a New Jersey climate with frequent swings in outdoor temperature, these constraints created clear risks:

- Higher fuel consumption than necessary

- Greater wear on boiler and burner components

- Increased likelihood of comfort complaints and unplanned service calls

The plant needed a way to run stably and efficiently across a wide range of operating conditions, not just on the coldest days.

Solution: Selected Equipment and System Design Rationale

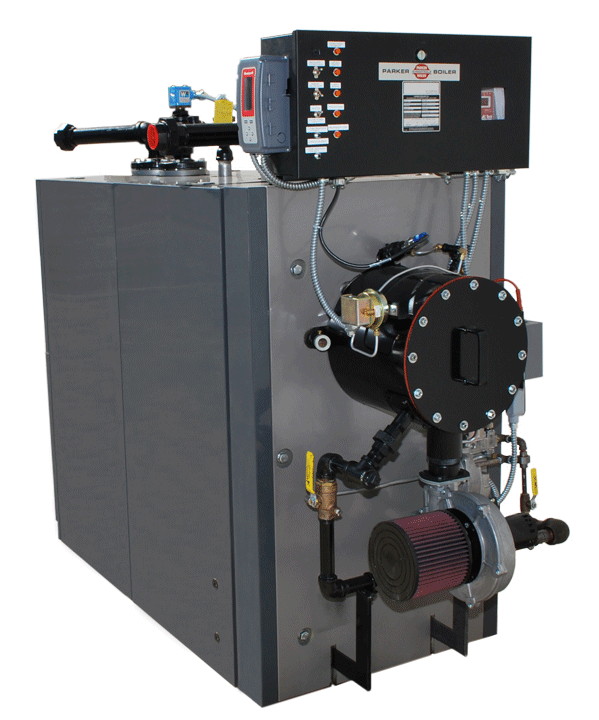

To resolve these issues, ICA supplied a Parker oil‑fired, condensing boiler fitted with an IC burner and controlled by a Siemens LMV 3 and RWF55 package.

This configuration was chosen because it:

- Improves heat transfer and part‑load efficiency

- Parker condensing design supports efficient operation at lower return water temperatures.

- Modernizes combustion management

- Siemens LMV 3 provides repeatable fuel‑air ratio control and reliable burner sequencing.

- Tightens load tracking and temperature control

- The RWF55 controller regulates temperature or pressure to better match building demand.

- Fits common New Jersey mechanical room constraints

- Compact footprint and service‑friendly layout support retrofit applications.

Together, the Parker boiler, IC burner, and Siemens controls form a targeted upgrade that raises efficiency, stabilizes operation, and stays practical to maintain.

Consultative Execution: Engineering Approach and Coordination

ICA approached the project as an engineering engagement, not just a boiler sale. The team:

- Assessed the existing system

- Reviewed load patterns and hydronic temperatures.

- Verified venting and condensate handling requirements for condensing operation.

- Coordinated with the installing contractor

- Addressed combustion air, flue routing, and mechanical room layout.

- Confirmed clearances and service access for long‑term maintenance.

- Supported commissioning and handoff

- Assisted with burner startup and LMV 3 / RWF55 parameter setup.

- Walked plant staff through setpoints, trends, and alarm handling.

This consultative support reduced risk during cutover and helped the facility operate the new boiler and controls correctly from the first heating season.

Results & Operational Impact: Post‑Installation Performance

After the upgrade, the boiler plant became more stable, efficient, and predictable. The facility saw:

- Smoother modulation and fewer on/off cycles

- The boiler tracks load more closely instead of short‑cycling at light demand.

- More consistent heating performance

- Supply temperatures are more stable, reducing comfort issues during mild or transitional weather.

- Improved part‑load efficiency

- Better combustion control and load matching lower fuel usage across the season.

- Better operational visibility

- Operators have clearer insight into system status and alarms, making it easier to shift toward planned maintenance.

Overall, the plant moved from a “run it and react” posture to a more controlled, observable mode of operation.

Why This Matters for Similar Facilities and Applications

Many New Jersey facilities are in a similar position: older boiler plants, limited turndown, and controls that no longer align with current efficiency and reliability expectations. This project illustrates how a targeted modernization can help:

- Commercial buildings that need better comfort and lower operating costs

- Light industrial facilities with variable loads and tight budget constraints

- Institutional sites that require stable, documented performance for stakeholders

By combining a Parker condensing boiler, IC burner, and Siemens control platform, Industrial Combustion Associates delivers:

- Higher efficiency at part load

- More stable and predictable operation

- A controls environment that plant staff can learn and use over the long term

This approach lets owners upgrade in stages instead of replacing an entire mechanical room at once.

Request a Free Specification Quote

Industrial Combustion Associates helps New Jersey facilities upgrade aging boiler plants with engineered, high‑efficiency solutions. If your building is dealing with short‑cycling, rising fuel costs, or outdated combustion controls, request a free specification quote to review your current loads, venting, and code requirements. ICA will evaluate your existing equipment and room constraints and outline a boiler and controls package engineered to improve stability, efficiency, and long‑term serviceability for your facility.